Cement Sandwich Panel Definition

Al-Ahram sandwich panel is light weight compound wall. The fibre cement board is surface panel, with cement, EPS as fillers. The product can replace construction materials like red brick, clay solid brick etc. It can be widely applied to various high and low buildings such as: family house, office building, hospital, school, and workshop.

Cement Sandwich Panel Advantages

- Easy installation: Tongue &Groove in the section makes the installation process easier. Al-Ahram sandwich panel is easy to cut with easy tools. Al-Ahram sandwich panel doesn’t need special labour. It doesn’t need paste on the surface of the sandwich panel.

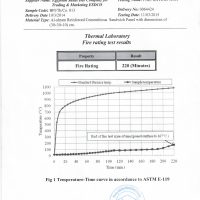

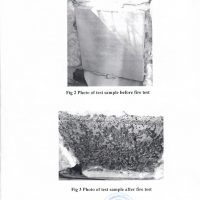

- Fire resistance: fire rate: 220 minute (ASTM E119)

- Strength & durability: the sandwich panel show high efficiency towards impact, shocks & friction

- Area saving: sandwich panel thickness is 10 cm, but the little thickness has no effect on insulation quality.

- Water & humidity resistance: Al-Ahram sandwich panel doesn’t affect with water or humidity.

- Ability to hang on Al-Ahram sandwich panel: using nails, more than 40 kgms can be hang on Al-Ahram sandwich panels.

- Environmentally friendly: free of asbestos or any hazard material

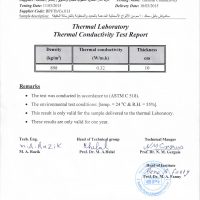

- High thermal insulation: due to existence of polystyrene so less energy is used for heating or cooling

Cement Sandwich Panel Specifications

| Specs. | Value |

| Thermal insulation | 0.32 Watt / k. m |

| flexure stress | 4.27 Mpa |

| Water content | 9 % |

| PH | 7 – 10 |

| Non – combustibility | Non combustible (BS 476 Part 4) |

| Fire rate | 220 minute (ASTM E 119 ) |

| Water tightness | No droplet under the panel under pressure 25 cm of water after 25 hours |

| Anchorage load | 45 kg |

| Acoustic insulation | 42 db |

Certifications

The thermal insulation & fire rate for cement sandwich panel

Cement Sandwich Panel Usages

1- The walls

Al-Ahram panel can be used in external and internal wall applications. It has high resistance for fire, water, impact and the external weather conditions. It also has high thermal and acoustic insulation in addition to its light weight. So it can be used as partitions to reduce the consumption of steel and concrete. It can widely be applied at all types of buildings like residential, administrative, industrial and medical…..etc.

2- Prototype Building

By using Al-Ahram panel a large number of Designs of buildings for any purposes can be performed from residential houses and administrative buildings to schools in remote areas and to speed installation, implementation, and ease of transport

3- Prefabricated Building

Using the floor, walls and roof systems produced by Al-Ahram Panel the prefabricated house can be built it has many advantage such as fast construction, durable and don’t effect with the different climate and in additions to it is environmentally friendly

| Main material for building with Al-Ahram sandwich panels | |||||

| The main frame | Frame | Steel structure

or Concrete structure |

Roof | Structural system | Steel

purlins |

| External wall | ESDCO Panel | Roof panel | ESDCO

Ferrocement floor 3 cm |

||

| Decorative wall | Esdco cement or gypsum boards | Ceiling | Any kind of ceiling available | ||

| Internal wall | ESDCO Panel | Floor | Structural system | Steel

purlins |

|

| Floor panel | ESDCO

Ferrocement floor 3 cm |

||||

4- Increasing an extra floor

Al-Ahram panels can be used for building an extra floor in any type of building such as: schools, hotels or even governmental buildings, as Al-Ahram panels are light weight & don’t affect on the structure.

5- The caravans

The caravans made by Al-Ahram PANEL not affect by the weather conditions & give more insulations in heat and sound and no need for cranes of transportations.

6- Fences

The fences can be done using Al-Ahram Panel by tongue and groove method save time and cost in additions to that is very effective in the remote places.

General instructions for Al-ahram sandwich panel installation

- According to the architect design the place of the Al-Ahram panel will be defined using U Channel to define the place of the walls

- Using electrocution saw the panel will be cut to the required dimensions

- Put the adhesive mortal concrete in the ground in the same place of the lines of the place of the panel

- Put the panel in the defined place on the Adhesive mortal concrete as the tongue is in bottom after breaking it and the groove is in the top and make sure the Mixing is filing with the panel base And using reinforcing steel bar to fix the panel in the ground and the floor

- Filing the both side of the panel with adhesive Mortar Concrete and then fix the both panel and then fix it together with steel bar 8 or 6 mm Diameter and using ruler bar to make Leveling

Paste

- Filling the gabs between the walls using putty and anti crack cloth